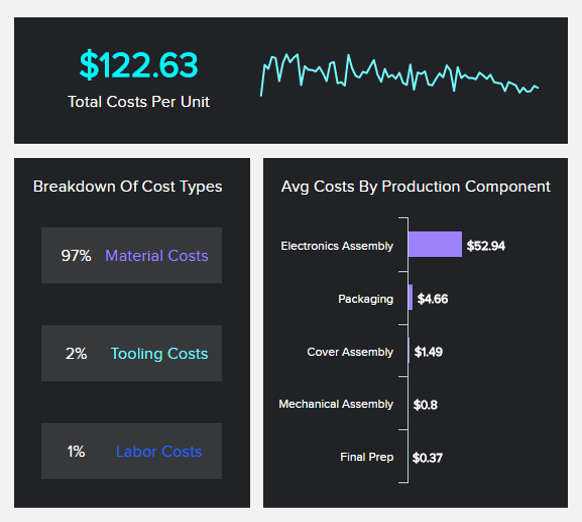

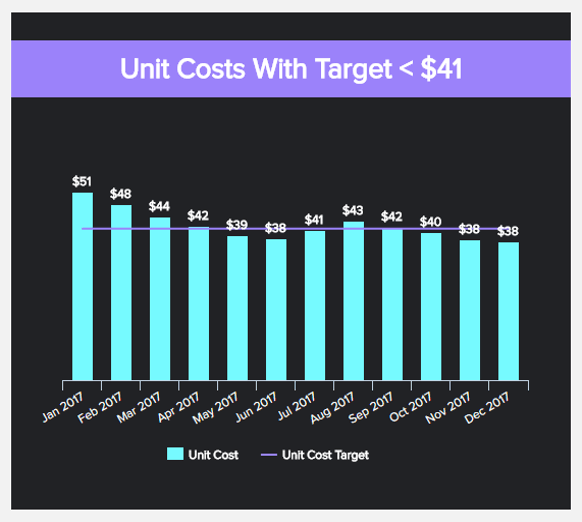

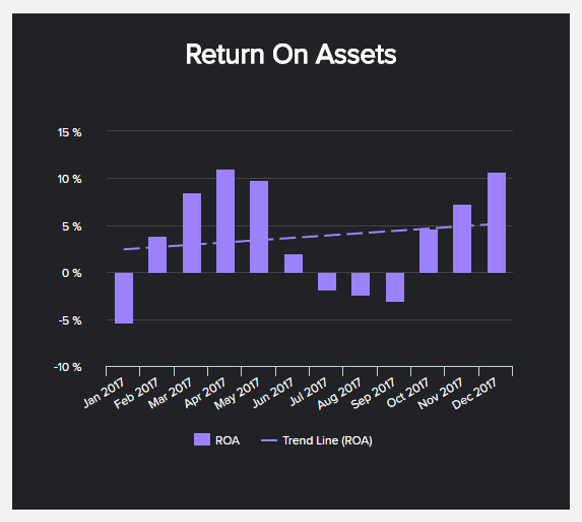

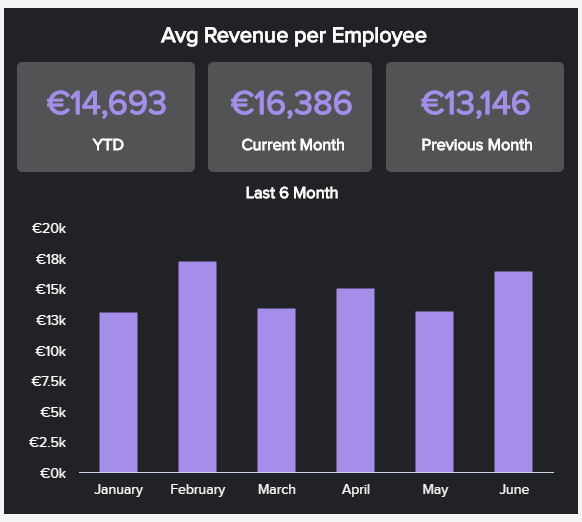

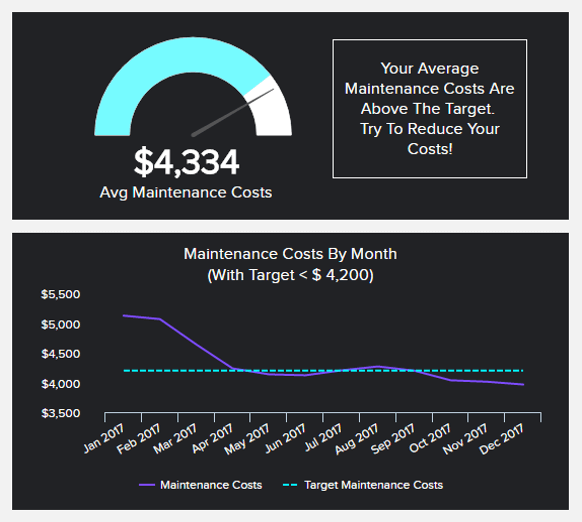

Maintenance Costs

Evaluate how much your equipment costsAfter assessing your assets, how much they produce, and the revenue you get from them you cannot let them wither, therefore maintenance is required. That’s why measuring this manufacturing KPI is critical to know which machine needs more work than others, where the resources should be focused, and what kind of preventative measures can be implemented to optimize that maintenance for the future. Set a target cost for correct maintenance that leaves enough money aside for other investments, and try to reach it. Compare your preventive and corrective costs, as the latter should be inferior to the former, if done well.

Performance IndicatorsTry to optimize maintenance costs over time and adjust your target accordingly.

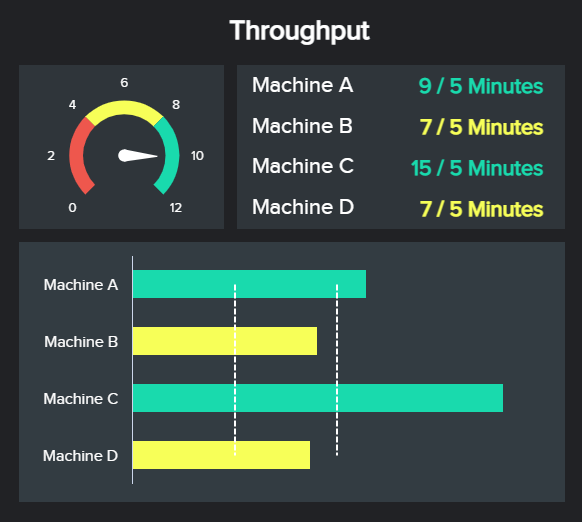

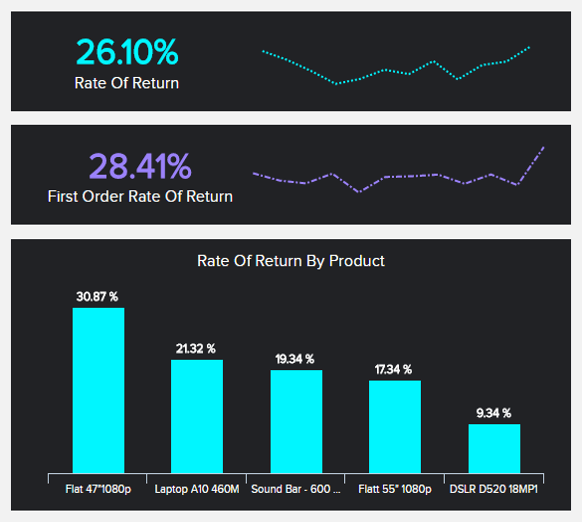

Relevant Showcase Dashboard