WHAT IS MANUFACTURING ANALYTICS?

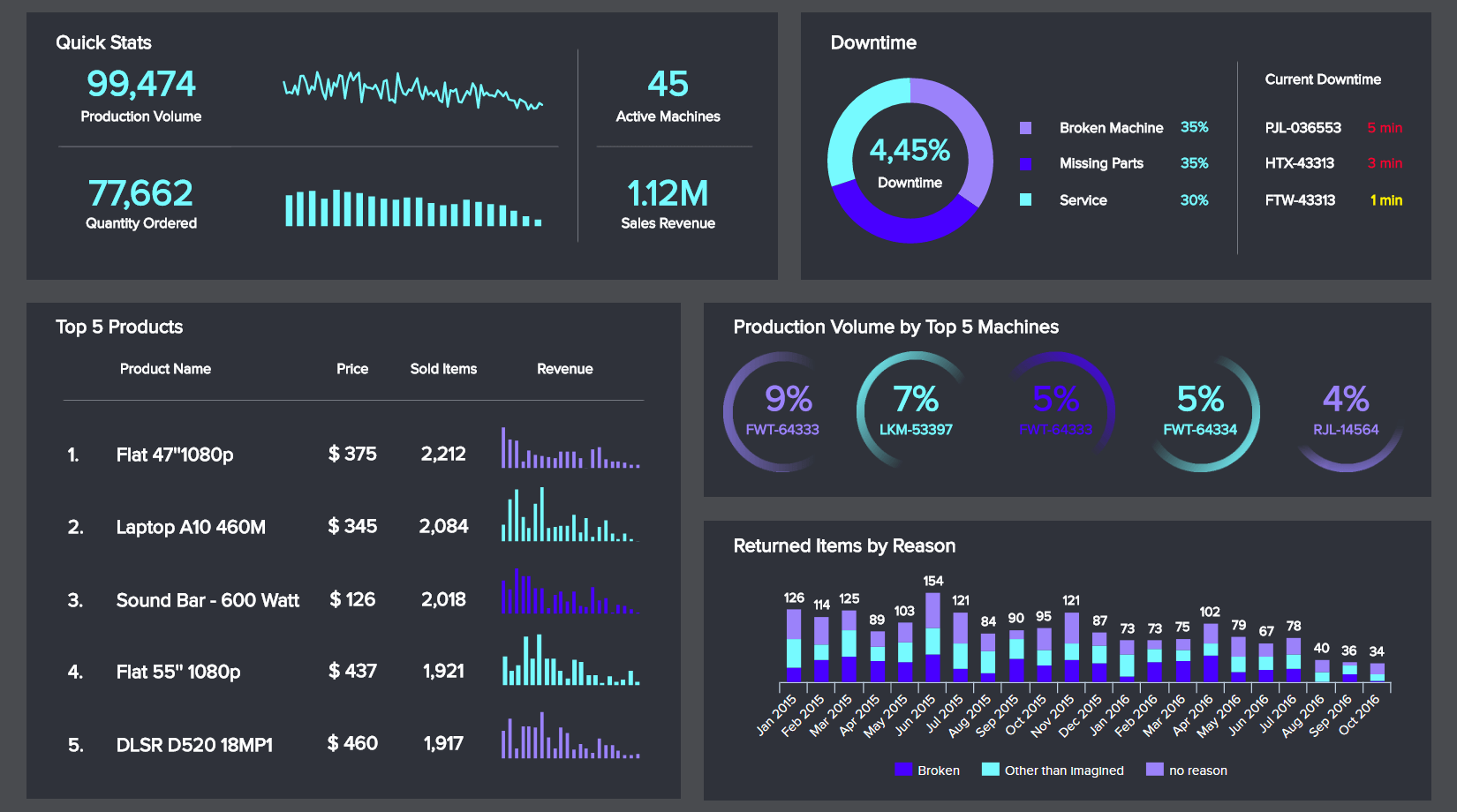

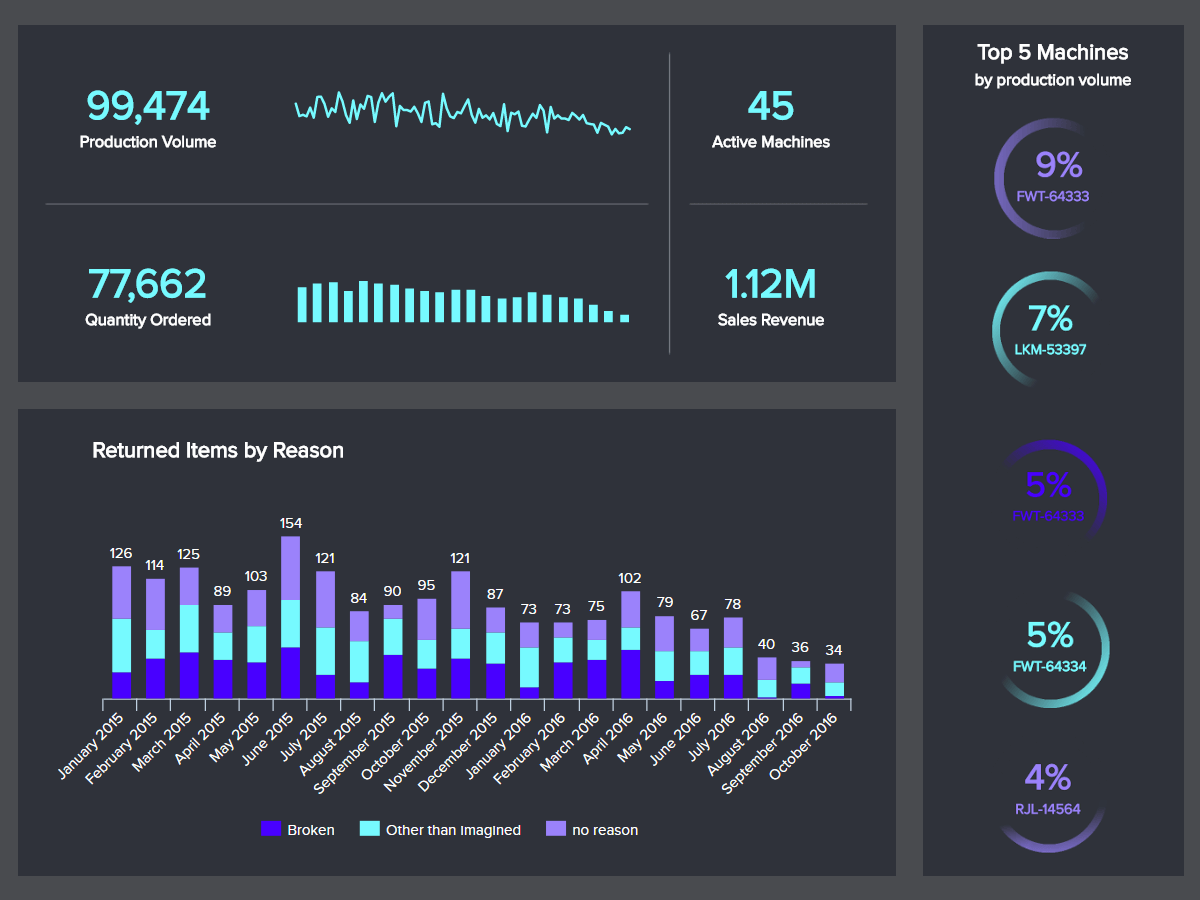

Manufacturing analytics is the process of capturing, aggregating, and analyzing key performance indicators such as production volume, downtime, costs, return on assets, among others, in order to optimize the production process and meet business goals. From the raw materials to investment, logistics and of course, the final product, manufacturing is an intricate process with many moving parts. Besides the non-tangible aspects of the manufacturing industry, there are financial and managerial aspects to oversee, not to mention a perpetually changing consumer demand and aggressive competition. However, in spite of all these complexities, there is a constant generation of data reflecting the manufacturing process. datapine’s manufacturing analytics software allows the nuances of this data to be harnessed and translated it into meaningful information on a professional manufacturing dashboard that can then be used to improve all aspects of the process, at any scale.

"datapine gives us all the insights we need in a compact space. Thanks to datapine we are able to review all relevant customer data and react on trends and opportunities much faster."

Kai Hansen

WHERE EVERY GEAR TURNS TOGETHER

In the manufacturing industry, there are simply too many moving parts, both literally and figuratively. Advanced manufacturing analytics can be applied for a more comprehensive and robust decision-making process.

- Enhance process efficiency and improve final product safety

- Don’t miss any relevant information at any production stage

- Gain a competitive edge by predicting future market trends

- Maintain a profound consumer base and ensure its satisfaction

- Analyze and optimize your product inventory management

Become a data wizard within less than 1 hour!

IMPROVE EFFICIENCY WITH THE RIGHT BI SOFTWARE

Manufacturing analytics is all about manipulating raw data, selecting the right manufacturing KPIs from existing processes and translating them into actionable information. This information can later be used to improve and modify all dimensions of existing processes, in order to maximize profit margins, manage logistics and improve product efficiency, quality or safety. Manufacturing business intelligence software helps you to develop industry-specific forecasts and to translate demand signals to allow for the most appropriate and cost-effective response. It will ultimately improve existing processes and dominate the competition. There are hundreds of moving parts in the manufacturing industry and thousands of steps to monitor. Data can be easily lost and important decisions neglected without the help of clear objectives, systematically driven methods of gathering and studying existing data. Manufacturing BI software like datapine take every piece of information and merge them to create a top-down overview of manufacturing processes that could not have been completed if only relying on manpower alone.

Let us show you how Business Intelligence can be beneficial to your company’s bottom line.

Read Blog Article

Mute the noise of your manufacturing data to focus on insightful and impactful KPIs.

View KPIs

Get an evaluation! Want to talk to us about how datapine can help your business?

Get in touchWhy is manufacturing analytics software important?

Raw materials being more expensive, harder to source, and a growing need to streamline operations: manufacturers are facing many transformations in their industry that lead them to find new ways to boost their productivity and profitability. Like many others, the manufacturing industry has dealt with disruptive changes over the past decade, and is still in an in-between situation of adaptation. Globalization, vertical integration or margin pressure are some of the many business challenges that force manufacturers to find new innovative ways to improve their decision-making, so as to perform better. This is where business intelligence in manufacturing comes in. By gaining actionable insights through manufacturing analytics tools, the decision-making process is streamlined while departments more connected.

Historically, the manufacturing sector has been a slow-changer, especially in integrating innovative IT solution. That is partly due to the fact their “IT” infrastructures were developed before the cloud was born, or before the inexpensive storage of data and the omnipresent connectivity were easily accessible. But the disruption forced the manufacturing industry to adopt new ways of working, and it is now catching up with the use of modern manufacturing analytics tools.

THE IMPACT OF IOT & MODERN MANUFACTURING ANALYTICS

The manufacturing revolution, generated a century ago with the invention of the assembly line, is still going on: automated processes and mechanization enabled by the information technologies provide the sector with an incredible amount of data that most company don’t exactly know what to do with. This is where business intelligence in manufacturing steps in, and helps you connect the dots: by gathering all your data sources in one single point of truth, you are able to analyze them conjointly, and to visualize trends and patterns in the data that wouldn’t have been otherwise possible. Besides, these cross-database analyses yield valuable information for manufacturers to improve their processes, by saving costs, improving the quality and the safety, improving the workforce efficiency, enhancing collaboration, and generally increasing the productivity. Whether a large enterprise, or small manufacturer – today it doesn’t matter – to survive in today’s competitive environment, manufacturing analytics is the way to go. The value of analyzed data can empower business owners to take advantage of data driven decision making by combining their data through various data sources and visualize trends that would otherwise stay untapped.

You may have already heard of IoT (Internet of Things), as the term is quickly gaining tremendous buzz across industries. Simply put, in the IoT, sensors and actuators are embedded in physical objects. These sensors can be embedded in anything from roadways to pacemakers. They are then linked through wired and wireless networks, often using the same Internet Protocol (IP) that connects the internet. In other words, everything around us is becoming connected. This isn’t science fiction and it is revolutionizing industries.

In particular, the manufacturing industry is realizing the enormous potential for cyber-physical systems to improve productivity in the production process and the supply chain. The IoT is so revolutionary for the manufacturing industry it has its own subset: Industrial Internet of Things (IIoT). In the IIot, connections exist mainly to produce physical goods for the marketplace as well as to maintain the physical assets of production. These technologies have the ability to drive what Klaus Schwab, German engineer, economist and founder and executive chairman of the World Economic Forum, has coined as the fourth industrial revolution; following the steam engine, conveyor belt and first phase of IT and automation technology.

At datapine, we believe that manufacturing analytics can bring an incredible change to the way processes, logistics, or product quality are managed. We want to ease the access to your data, and provide you with the manufacturing business intelligence software you need for advanced analytics. Decode complex manufacturing processes and improve their operability, optimize maintenance costs, calibrate time reduction, assess risk and failure, implement root cause analysis, and detect anomalies: all of these insights are within your data, and you just need the right tools to uncover them.

USE THE BEST MANUFACTURING BUSINESS INTELLIGENCE SOFTWARE

Products are usually the core of any manufacturing business, so when it comes to implementing manufacturing analytics, they naturally are oriented towards product development. But it is not restricted to this area, and supply chain optimization or financial management overall improvement are also in the frontline of change. Whichever you decide to choose, focus your analytics on one targeted business area to produce better results, even if the launch of an enterprise-wide analytics initiative can be tempting – such strategy is much riskier, time-consuming, and expensive. Direct your attention on specific business questions that you need to answer to glean actionable insights that can have a major impact on your performance.

The use of manufacturing analytics can also enable new revenue models designed around selling services and not only improving the production process. Focus on some business issues, how to address them, and implement the right metrics to measure advancement in the project. With the business objectives set, develop your strategy that complies with the priorities pre-fixed, and assess the results after a certain time. Depending on your findings and what you learn, adjust the strategy or reinforce the measures in place.

Become a data wizard in less than 1 hour!